Rotomes

- Home

- Rotomes

Request a

DEMONSTRAÇÃO

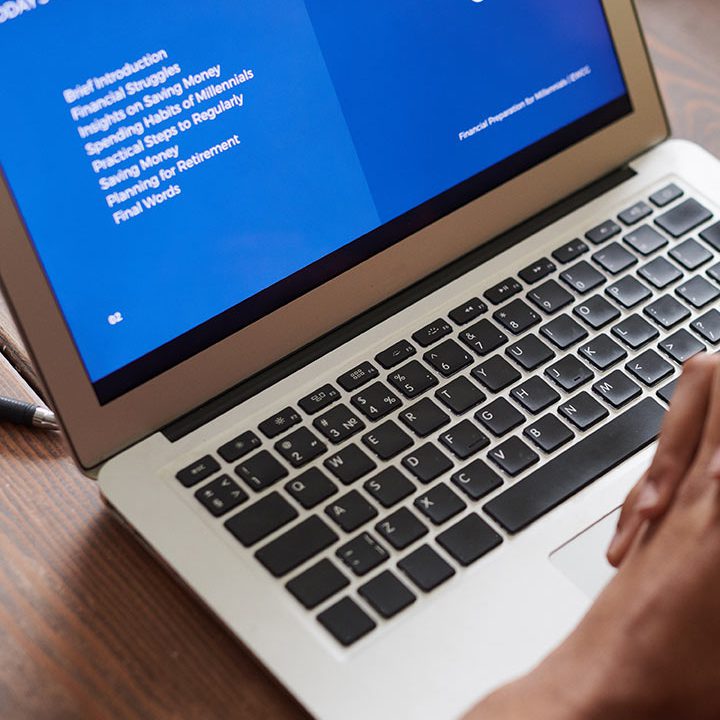

RotoMES

THE FIRST AND ONLY MES EXCLUSIVELY

FOR ROTOMOLDING

Monitor the performance of industrial equipment

in real time

Optimize your production

results with

RotoMES!

With RotoMES, your industry can monitor and track, in real time, all operational data and information from rotomolding machines — whether directly from the factory or remotely.

Allcance offers customized MES systems for different types of machines, allowing precise measurement of Overall Equipment Effectiveness (OEE). This includes essential indicators such as:

Availability versus

potential usage

Productive performance

Process quality

MAKE THE MOST OF

your production potential

The first MES (Manufacturing Execution System) exclusively for

rotomolding machines, developed by Allcance, manages

all production processes in your industry, offering

essential indicators such as:

Availability versus

potential usage

Arm occupancy

percentage

Failure log and

recurring issues

With RotoMES, Allcance consolidates its market differential,

providing an innovative solution that integrates directly with

rotomolding machines.

This enables precise monitoring, cost reduction, and

increased production efficiency.

Thus, your industry

adds benefits, such as:

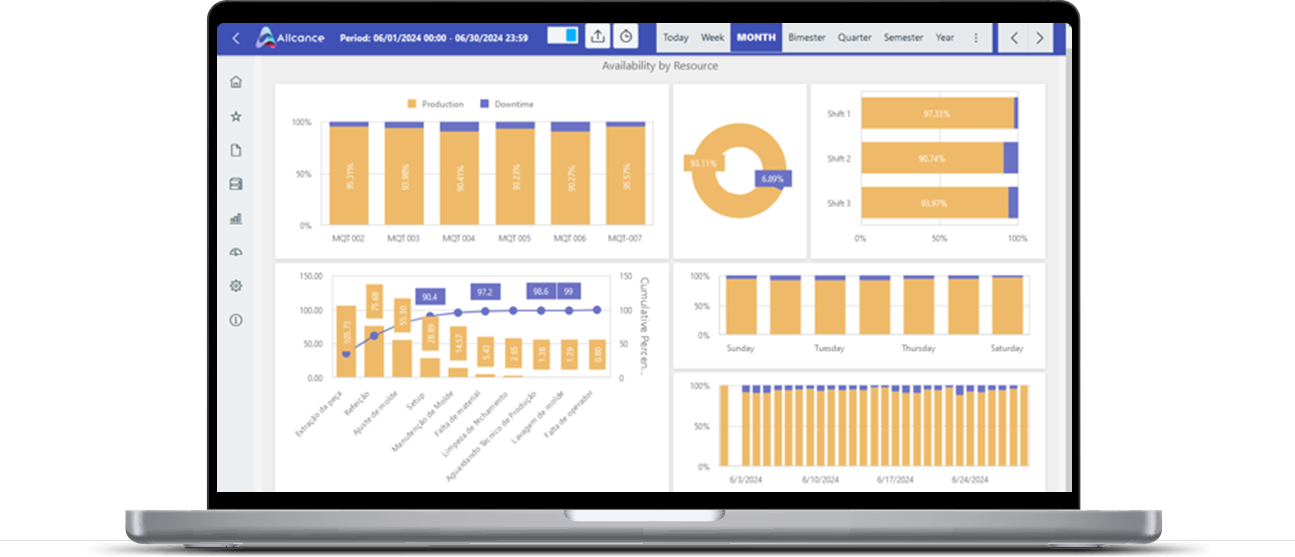

1 - AVAILABILITY

Monitor production in real time with information such as production list, executed cycles, alarms, sensor status, and oven downtime reasons/times.

2 - PERFORMANCE

The integration of your machine with management systems, combined with information such as cycle time measurement and arm occupancy, allows the automation of tasks and processes, optimizing equipment usage and increasing productivity.

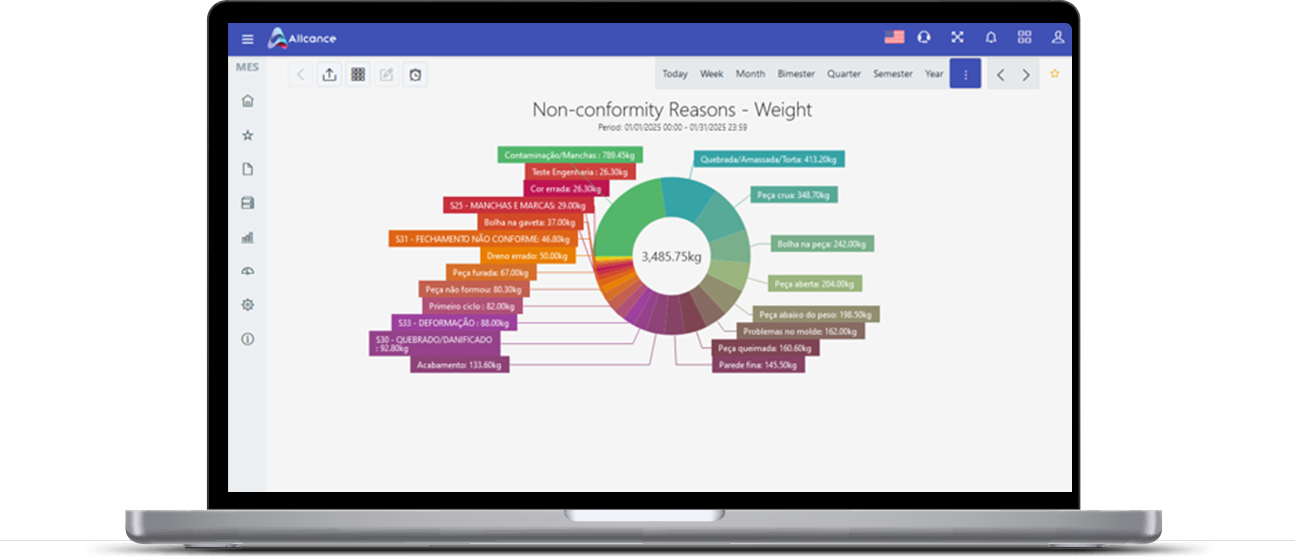

3 - QUALITY

Start monitoring production quality more quickly and efficiently, identifying potential issues before they cause damage to products.

4 - COST REDUCTION

The real-time identification of waste prevents bigger problems and contributes to cost reduction. Increasing OEE also lowers production costs, allowing the company to produce more with the same resources.

ROTOMES

offers KPIs and immediate

alerts for equipment

issues

Imagine being able to identify an arm stopped in the oven during a cycle without any human interaction or monitoring. This is possible through RotoMES, which uses cutting-edge technology and smart intelligence to detect problems. In addition, it issues immediate alerts and alarms to the manager for the necessary adjustments.

Fault detection

Risk and problem

identification

Immediate alarm

issuance in case

of problems

KPI monitoring

All equipment indicators

detailed

ON your screen

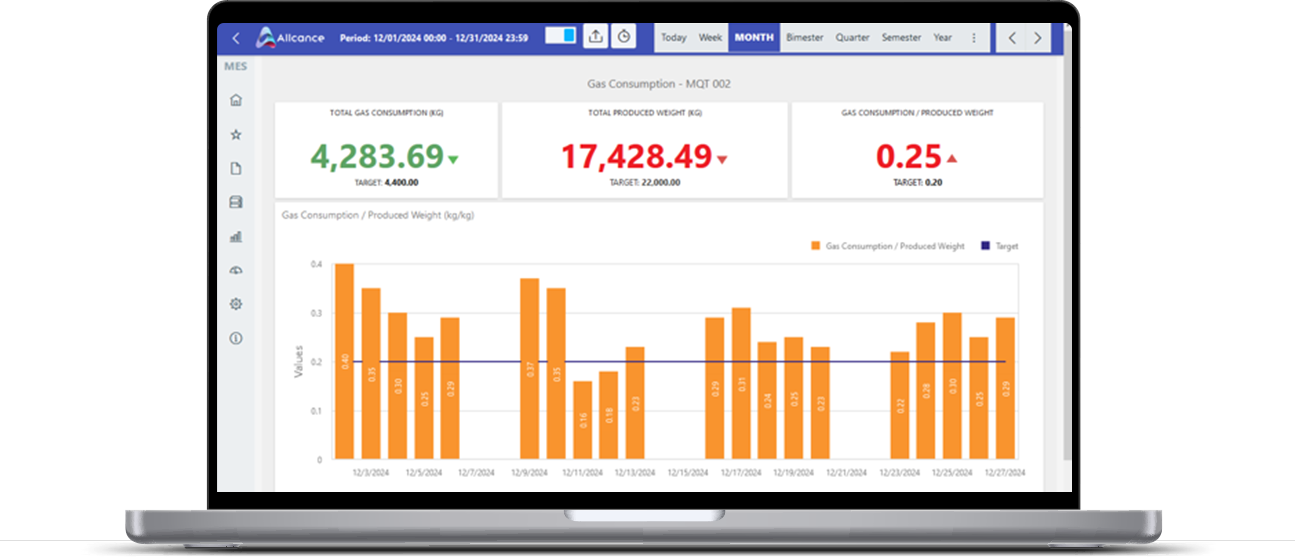

With RotoMES Allcance, gather essential data and information from your equipment

through intuitive dashboards and key indicators.

Everything you need to measure about your production can be just a few

clicks away, whether from inside the factory or from anywhere, at any time.

Take advantage of all the features, such as filters, dashboard templates, reports,

timelines, and charts to monitor the full performance of your equipment!

Check out

some examples

of indicators:

Experimente sem custos adicionais

Experience the efficiency of RotoMES in practice with a personalized demonstration and see the first results before investing.

*The Allcance system can service machines of other models.