Now we are

Allcance Tecnologia

In the year 2000, Holma Software was born, marking the beginning of the development of the software we live with today. In these more than twenty years, the world has evolved significantly, and it wouldn't be any different for us. We have evolved our brand, our name, our technologies, and our software, becoming experts in Industry 4.0 Software.

Welcome to Allcance, a company with 23 years of history and over 300 clients.

Experience

23 years developing software.

+300 clients

Clients satisfied with real results.

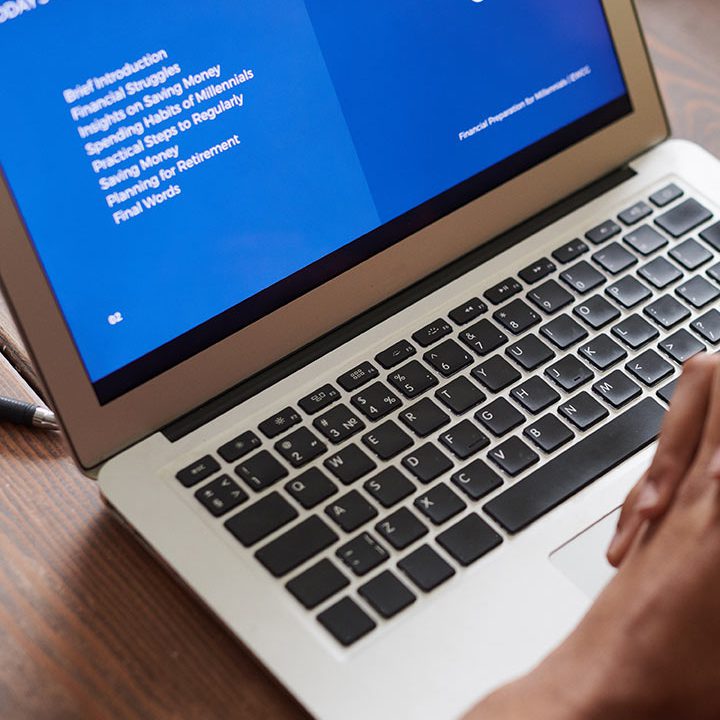

Does your industry need to change?

How we will help you

// ERP - Management system for industry

MES - Starter

MES - Enterprise

ROTOMES

APS – Advanced Planning and Scheduling

Developing software.

With 21 years in the market serving various industries from small to large scale, we have confidence in our software.

Active clients

With a portfolio of over 300 clients, we stand out for our commitment to delivering real and reliable results.

Complete management

in different segments

Food

Dairy, meatpacking, various sweets, and beverages.

Metal Structures

Sawing, cutting, bending, machining, stamping, assembly, welding, and painting.

Concrete Structures

Reinforcement, concrete, and molding.

Fuels

Crushing, neutralization, refinery, and biodiesel.

Plastics and Rubber

Injection, extrusion, blow molding, thermoforming, and rotational molding.

Agricultural Machinery and Implements

Sawing, cutting, bending, machining, stamping, assembly, welding, and painting.

Parts and Accessories

Sawing, cutting, bending, machining, stamping, assembly, welding, and painting.

Electronic Equipment

Poultry automation, vehicle tracking, sound equipment.

Road Machinery and Implements

Sawing, cutting, bending, machining, stamping, assembly, welding, and painting.

Let's transform

your industry now?

Software that delivers real and reliable results.

Real-time management with data from all areas of the company, enabling informed decision-making, minimizing errors, predicting situations, and increasing results.

23 years of history

more than 300 clients

Mauricio Scorteganha

Industrial Director at Tecnotri.

Joanir Verdi

Production Manager at Tecnotri.

Eng. ME.: Jeferson Rigo

Managing Partner at Veloce Industrial.